Do you want to apply advanced artificial vision?

Who you gonna call?

Automated inspection is critical these days. Leading-edge vision technologies are amazingly powerful and capable of undertaking the most challenging applications.

Those who enable, those who bring systems to life have to be experts at better implementing and adapting these to the changing circumstances and growing requirements that are natural to the production floor.

This requires true craft. This requires an elite formation.

This requires a VISION COMMANDO.

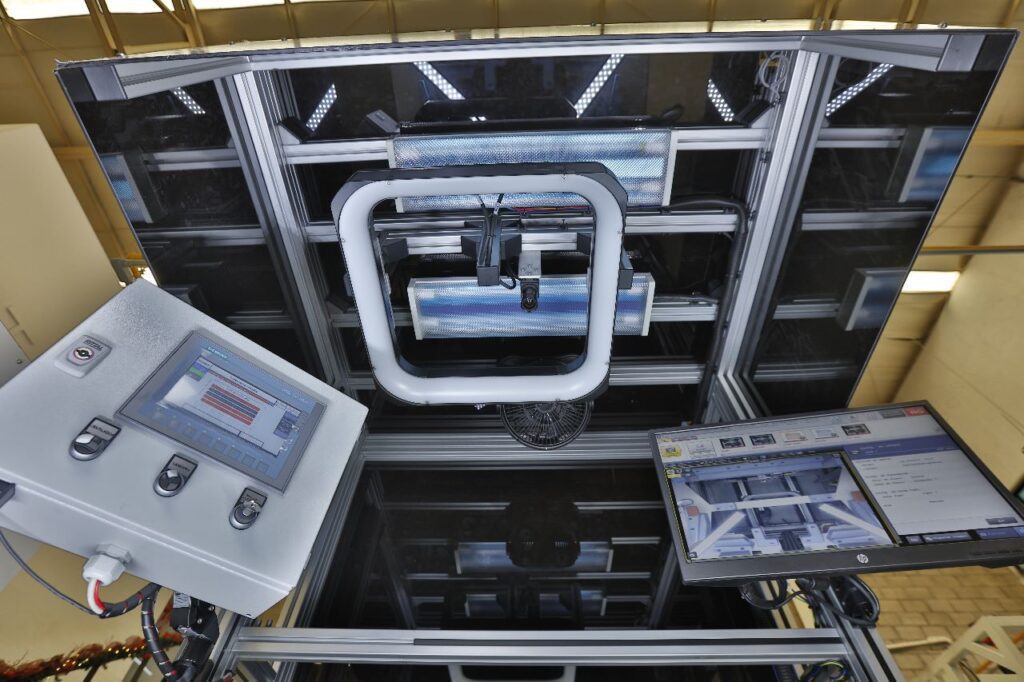

Full-production line developed by ST, with loop conveyor with pallets to ensure proper position before entering the inspection cabin.

Frontal and lateral inspection cabin with HD cameras placed frontally at 3 levels, with different angles to adapt to the shape and geometry of IP and capture images through a line scan motion; another set of HD cameras placed laterally to capture sides; infrared illumination to highlight clips, staples, and foam to be inspected for presence/absence and position. Once images are captured, they are “sewn” through programming to render the image of a complete inspected IP on the inspection screen. This required a highly complex automated compensation of gaps, field depth, focus, contrast, space between image and image, etc.

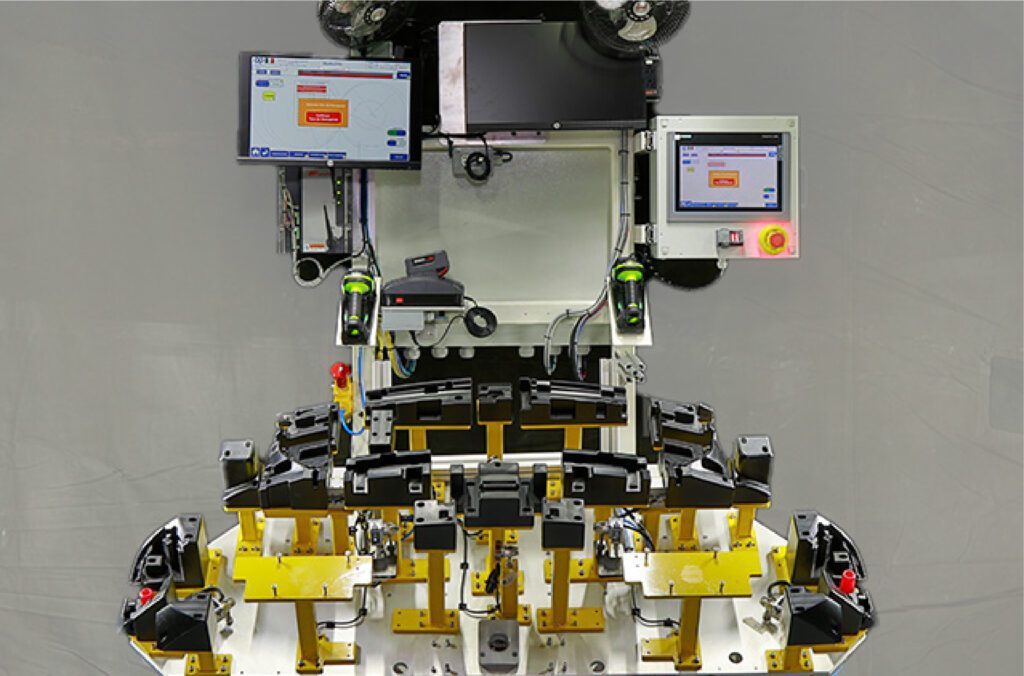

-Clean room application.

-Mounted on existing production line conveyor.

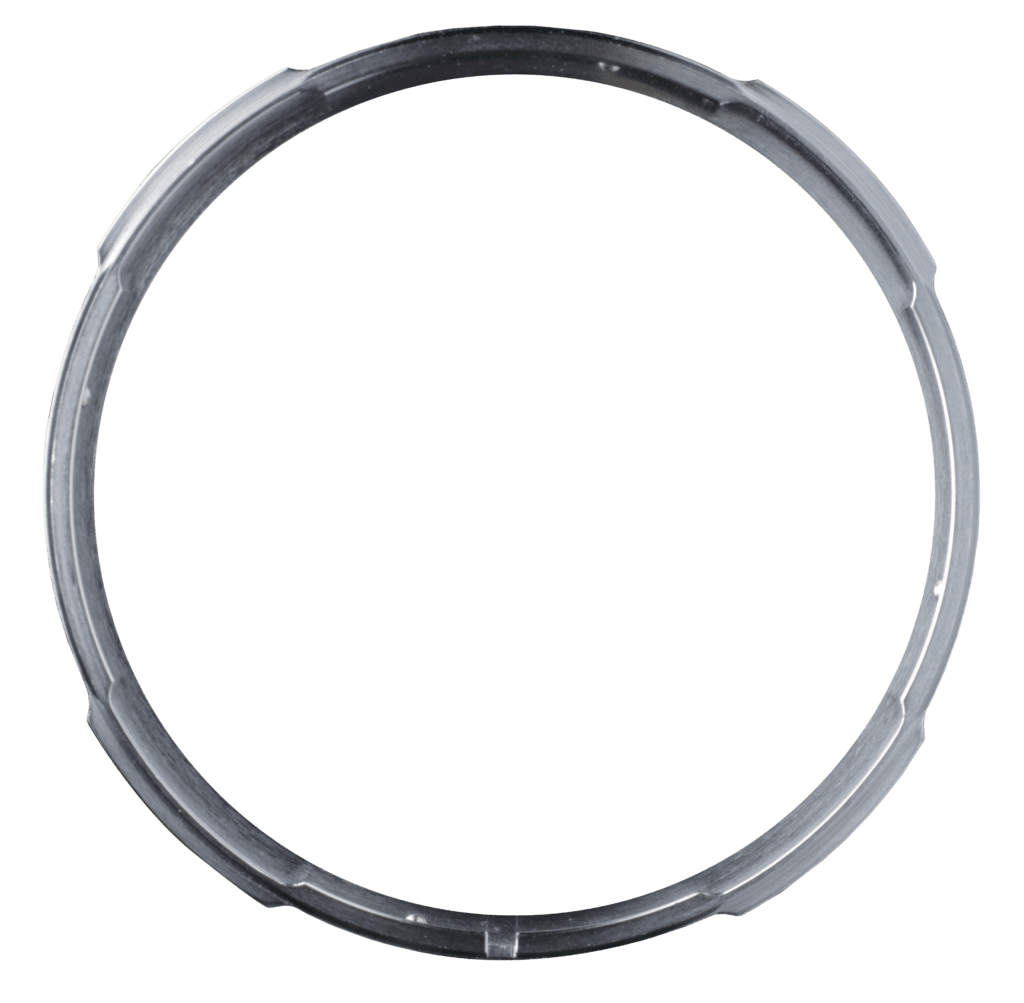

-Highly critical inspection as incorrect product filling of bag –due to incorrectly identified bag- could seriously affect the patient.

Unfilled bags -previously marked with the lot and product version- are run indistinctly on the line. Inspection cabin with a camera reads and validates the information, including the product to be filled, allowing the bag to move on to the filling stage if OK.

-Mounted on existing production line conveyor.

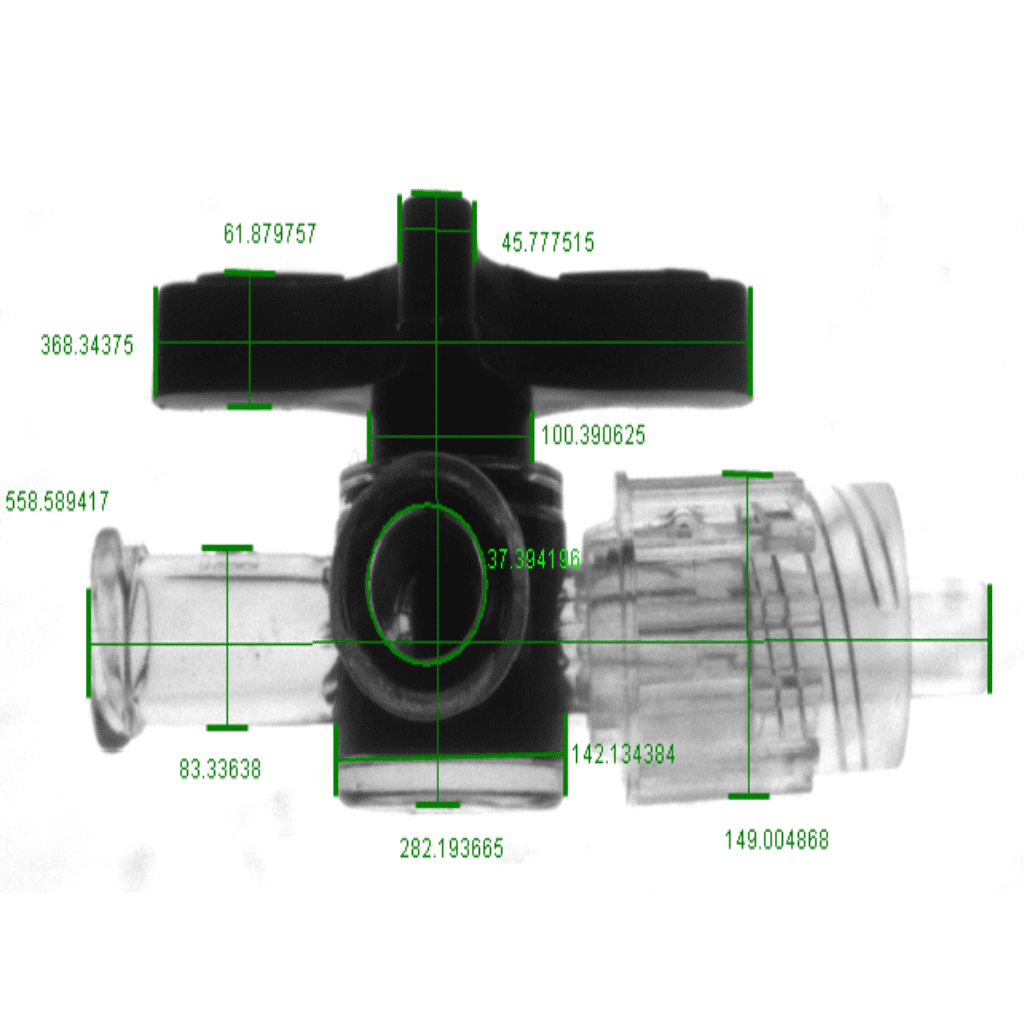

Products of the IV start kit are run indistinctly on the line. Inspection cabin -with HD camera and backlight illumination to create contrast on transparent, plastic product- detects product type, detects and counts parts, and measures the dimension of each to ensure the product is functional and according to quality standards.

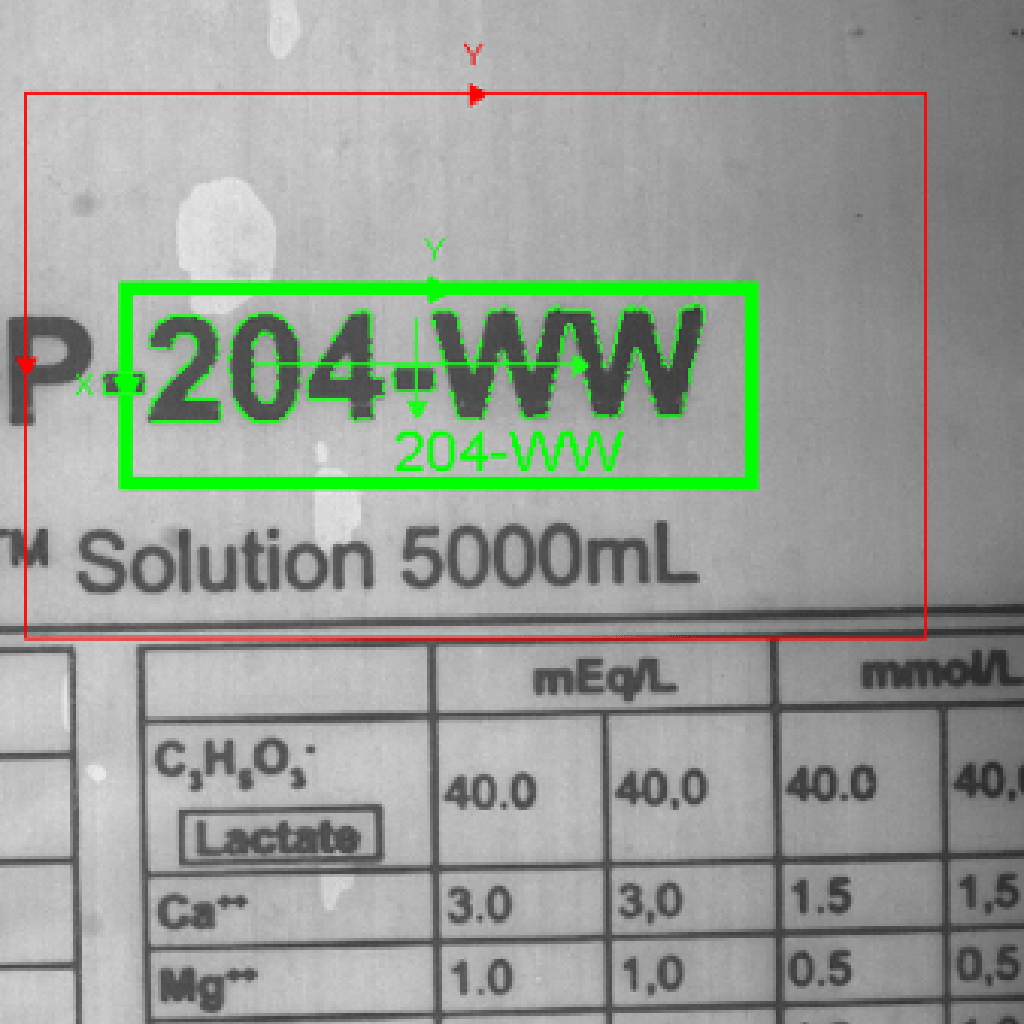

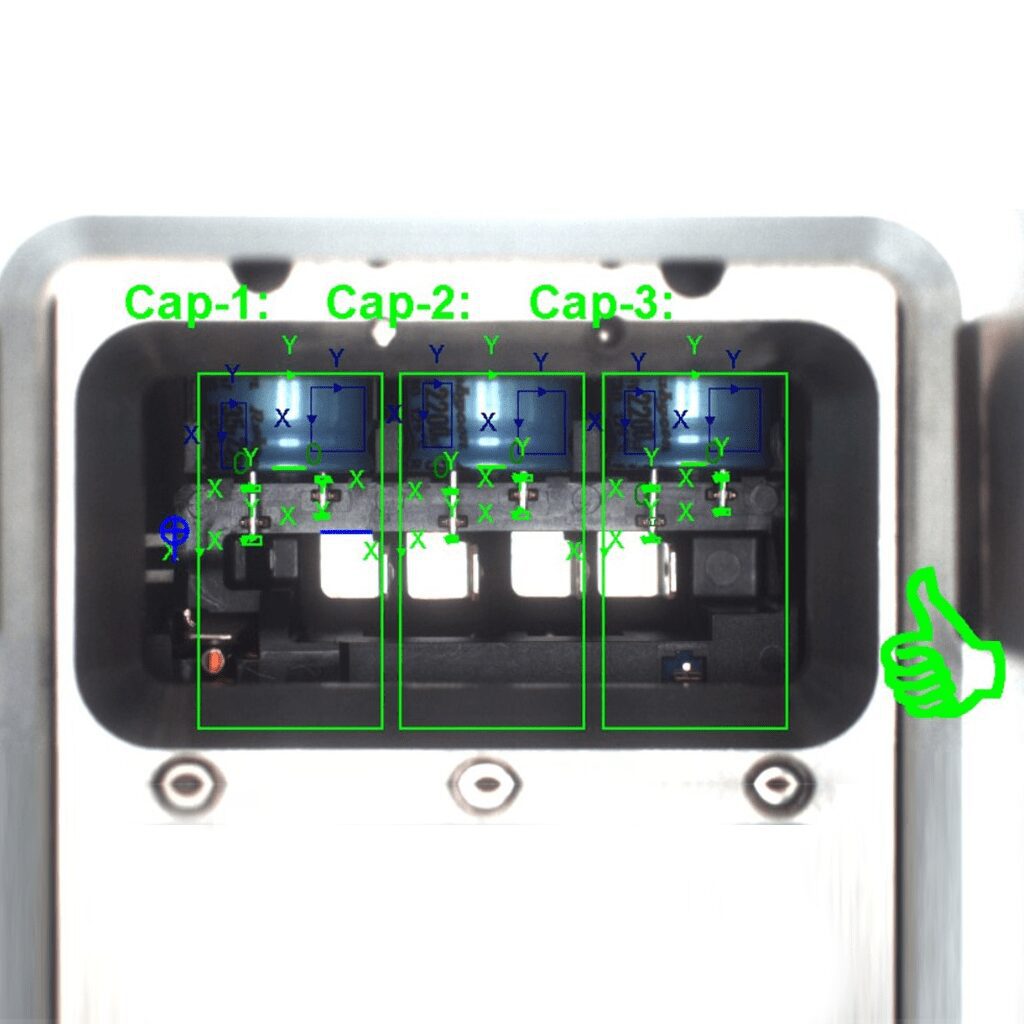

-PCB for the control of automotive headlights.

-Mounted on existing fully automated production line, within testing and assembly existing cabin.

An HD camera -perpendicularly placed on the line, with a low-angle red illumination, and a low distortion lens- inspects the presence/absence -as well as counts- of pins through the detection of the metal glare caused by the red illumination. Additionally, deformed or fractured pins are detected by inference, through the measurement of pins.

-Full-process control and traceability for fiscal control purposes.

-Assures the presence of a full, readable tax stamp; custom-developed software keeps count of used and discarded serial numbers (due to bottle breakage, missing or defective tax stamp from roll).

Warehouse reception: Tax stamp roll is scanned to detect available serial-numbers lot. At the production line: 1- Tax stamp on the bottle is scanned, the stamp is detected and read, if OK, registers the serial number, if NOK, the serial number is inferred through the sequence and discarded; 2- Second scan is executed before packaging to discard tax stamps of bottles that broke during the process; 3- If after packaging -when weighing the package- broken bottles are detected, a third scan is executed to discard tax stamps of the bottles that broke.

Our robust methodology and proficiency in the development of vision applications allow us to become our customers’ allies for continuous improvement at a production floor level.

Located at the ST Labs building, our Vision Lab empowers VISION COMMANDO’s capacity for the evaluation and testing of applications to ensure every solution presented to our customers is a proven and robust solution, for no-nonsense, straightforward, successful projects.

Preferred Vision Systems

Lenses and Illuminations

As Senior System Partner Integrators for Cognex, all levels of Cognex technologies and software -from ID to Vision Pro, to the new AI-powered VIDI- are expertly applied for the crafting of robust vision solutions.

Keyence is one of ST’s preferred overall technology brands for high-end sensors, safety equipment, vision technologies, laser marking, etc. For customers, Keyence is one of the friendliest brands for maintenance and future adjustments or modifications.

Dalsa is a key vision technology for ST due to the potential of their special HD cameras but most importantly, due to the flexibility they provide, allowing for custom development of the software that the camera will run, for special applications jointly approached between our VISION COMMANDO team and our Software Team (from the Smart Testing Line).