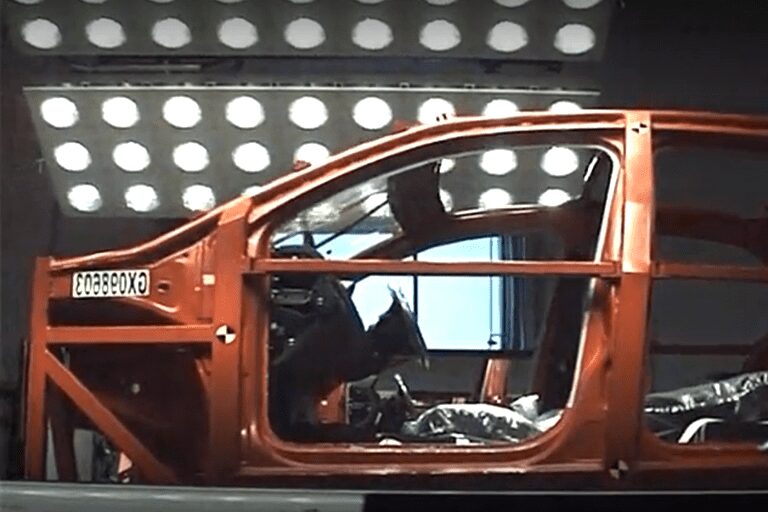

Our three decades of experience in complex, highly demanding industries, make us key partners who can swiftly and seamlessly adapt to your needs. We are highly knowledgeable in the automotive industry; other well-known industries include aerospace, electrical & electronics, consumer goods, pharma, and food & beverage.

Required professionals (specialized engineers or qualified, skilled technicians) at your call.

Hourly, daily, weekly, monthly

Remote / At ST’s site / At customer’s site

As required: As small as 1 professional / When hiring a task force, an ST team leader is included as the liaison between the task force and the customer.

Coordinated by customer.

May be included depending on the task and availability.

Not included.

Undefined, as ST’s professionals or task force is coordinated by customer.

Required professionals (specialized engineers or qualified, skilled technicians) applied to the execution and completion of a defined scope.

Duration will be set according to the scope.

Remote / At ST’s site / At customer’s site

As required: As small as 1 professional / When hiring a task force, an ST team leader is included as the liaison between the task force and the customer.

Coordinated by ST.

May be included depending on the task and availability.

Not included; refer to optionals.

Completion of the scope, within the defined duration.

The By scope modality can be quoted in a Time & materials modality.